This week’s podcast is about JD Logistics, which is building a smart logistics network at China scale. I spoke to one of its heads and this is what I learned.

You can listen to this podcast here, which has the slides and graphics mentioned. Also available at iTunes and Google Podcasts.

Here is the link to TechMoat Consulting.

Here is the link to the China Tech Tour.

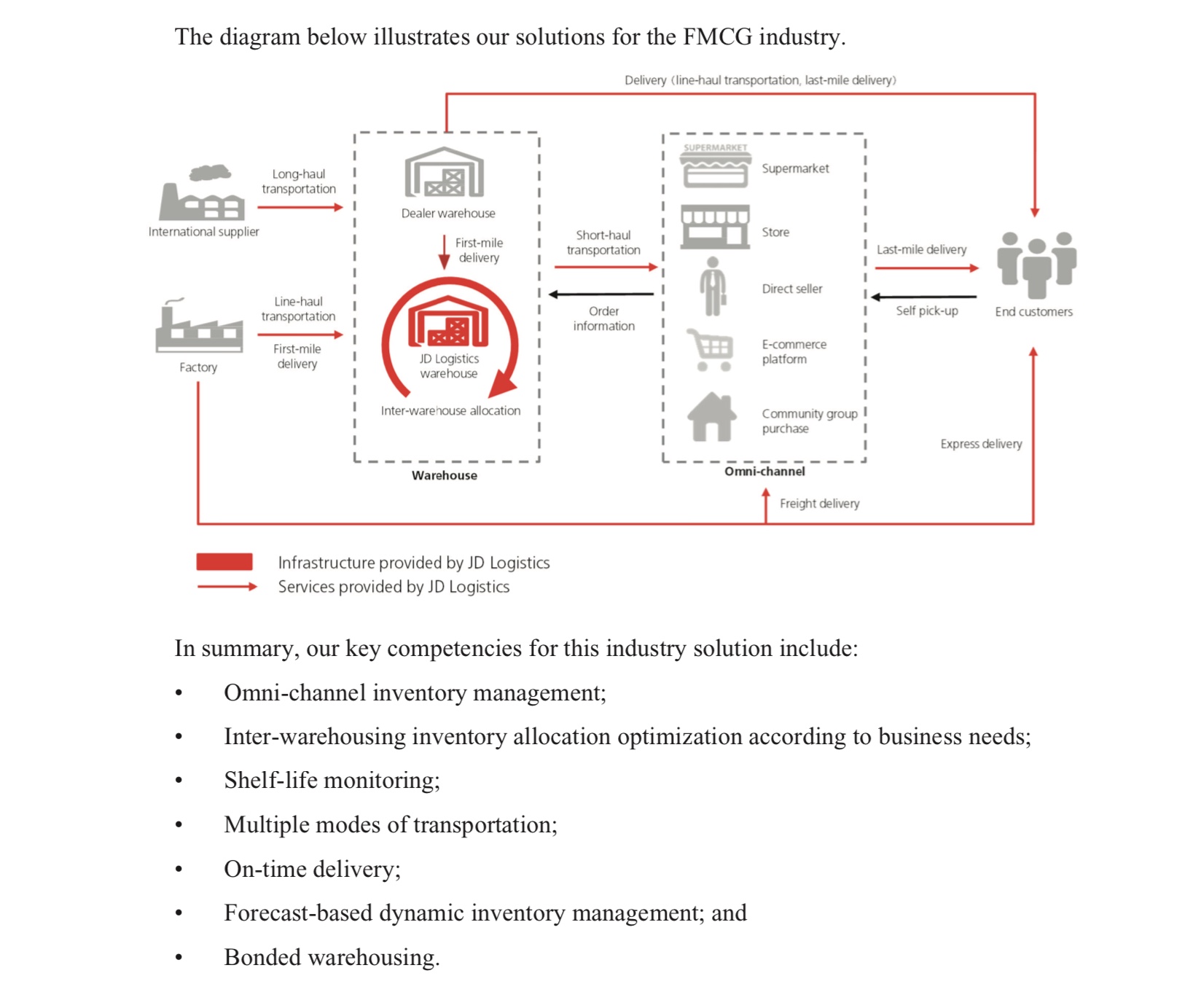

Here is the slide mentioned:

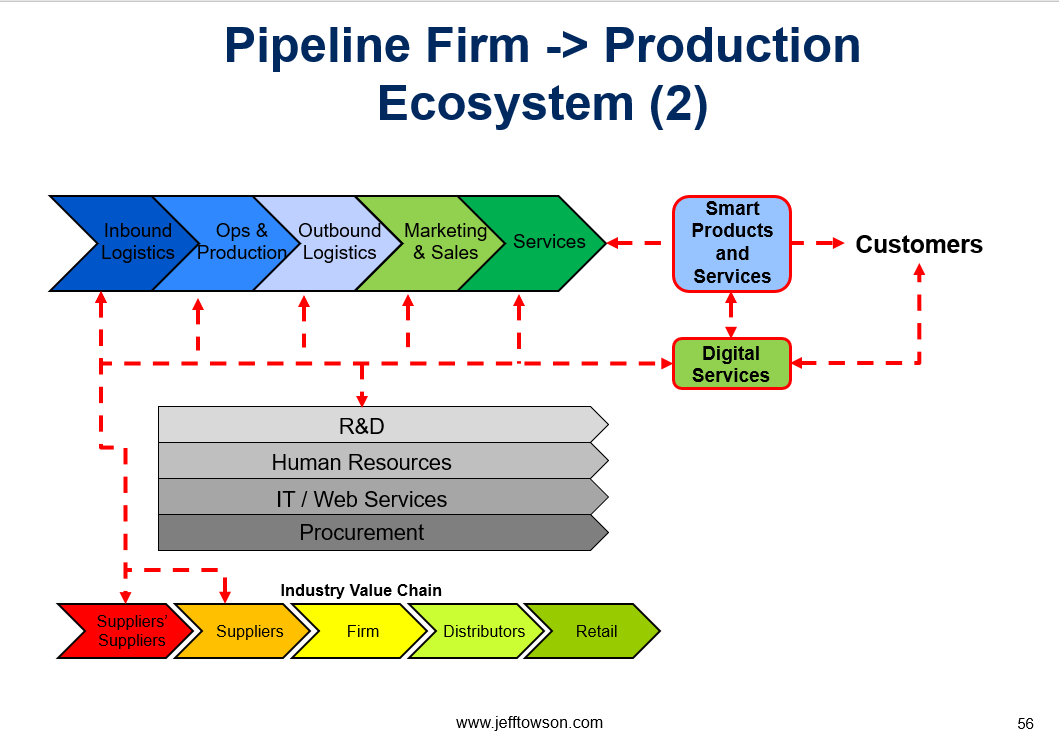

Here is a Production Ecosystem

From the Concept Library, concepts for this article are:

- N/A

From the Company Library, companies for this article are:

- JD Logistics

- JD

Welcome, welcome everybody. My name is Jeff Towson and this is the Tech Strategy Podcast where we analyze the best digital businesses of the US, China and Asia. And the topic for today, four things I learned from the head of JD Smart Logistics Park. Now JD Logistics, which is part of JD, the smart automated IoT logistics network they’ve been building for a long, long time. I think it’s one of the most important things going on in digital anywhere. There’s only a couple companies in the world really building out. what I’m calling a smart logistics network, but it’s not totally clear what this animal’s gonna be. JD’s one of them, Amazon’s one, Alibaba’s one. Anyways, a while back, I had an interview with the head of the smart logistics park for JD, and I hadn’t really gotten to sort of writing it up and thinking about it. I kinda got sidetracked into generative AI, but I wanted to talk about it, because it’s a super important subject. I really think China, Asia is probably going to be the leader in this for various reasons having to do with urban density and other things. So anyways, I want to kind of talk about what I learned from that. And I think it’s, you know, I thought it was really fascinating talking to them. So hopefully you will as well. Okay, so that’s the topic for today. Let’s see, I guess, kind of important. I am doing the China Tech Tour in several weeks, June 12th to 16th. Now we do one of these in the spring, we do one in the fall, but we’ve actually split the spring group up into two separate tours. There wasn’t a lot of overlap between e-commerce and auto. So we split that up. So the smaller group is going June 12th to 16th, the other one shortly after. And we still have some spots, if you’re interested in doing that, there’s time to do it if you give me sort of an email or a call, sort of ASAP. And the two are details, which we haven’t really talked about until now, because you’ve got to confirm stuff, right? It takes a bit of work, actually. It’s going to be Beijing, Shanghai, Hangzhou. Going to JD Logistics, Smart Logistics Park. Going to JD headquarters, e-commerce leader. Going to Baidu, who is, if you’ve been paying attention, is arguably the generative AI leader of China at this point. iQiyi, and they’re also big in auto, autonomous driving. iQiyi, which is arguably the leading sort of YouTube meets Netflix business model. So you can see we’re trying to hit related to sort of e-commerce, which is not all of them, but you know, e-commerce, smart logistics, media, entertainment, you wanna hit all of those. Especially in China where things are really pretty great. And that’s Beijing, they’re heading to Hanzhou, Ant Financial. going to visit them, Sanyao Logistics, which is Alibaba’s logistics arm, probably other parts of Alibaba as well, heading back to Shanghai, doing some lectures. Anyways, it’s going to be a spectacularly fun trip and we’re visiting sort of a who’s who of the, really some of the best companies in Asia and that makes them really in the top of the whole world in my opinion. Anyways, that’s coming up June 12th, June 16th, if that’s something you’re interested in give us a call ASAP. is how to take a little bit of discussion but otherwise yeah go over to the easiest way to reach me is LinkedIn and just send me a note or info at thousand group com okay and with that let’s do the standard disclaimer nothing in this podcast or my writing a website is investment advice the numbers and information from me and any guess may be incorrect the views and opinions expressed may no longer be relevant or accurate overall investing is risky this is not investment legal or tax advice do your own research And with that, let’s get into the topic. Now I don’t really have any concepts for today. Maybe just innovation platforms, we’ll talk a little bit about that. I’ve talked about that many times, but that’s in the concept library on the webpage. And yeah, that’s probably about it, but just logistics is it’s kind of its own animal. You know, this is one of those, I’ve been looking at logistics for a long, long time, and mainly because Warren Buffett has been investing in logistics. Um. Let’s call them networks for a long time. DHL, companies like that, FedEx, which have really interesting dynamics and they do tend to collapse to a giants and dwarfs scenario. I mean, there’s just a handful of these internationally and we see that with a lot of networked based businesses like payment networks are that way, logistics networks, DHL, FedEx, things like that. And we see that pretty much everywhere. But I’ll talk about they are different. of you who sort of bought my books and stuff, they’re not quite… I mean one of the big differences you think about is if you’re looking at logistics, it’s kind of a two-sided platform a little bit. We have people who are sending a package and people who are receiving a package. So it’s two user groups, kind of. A little bit like payment. People sending money, people receiving money. But because it’s not digital, because it’s physical, it doesn’t operate like a MasterCard or a Visa, where every single person, every single user, connects with every other user. That’s one of the reasons digital networks, starting with really phone lines, were so much more powerful because every new user you added could talk to every individual user. So it’s a very hyper networked, right? Physical networks don’t look the same. They’re usually what people call radial networks, where all the packages, let’s say in Shanghai, all go to a warehouse on the outside of town or usually the airport. And it goes to a hub and a spoke system. Shanghai will fly out at midnight and go to Beijing and they’ll go to Shenzhen. They’ll go to a certain number of cities. But you have this hub and spoke system also called a radio network. So as a result of that, the number of connections that each person has directly is not quite the same as I can pick up my phone call everyone direct. It’s got a route through these sort of hub and spokes. And that tends to give them somewhat of a network effect, but nothing like we see when every user connects with every other user. So often they call this like connection density, and there’s ways you can put numbers around that. So it’s a little bit different. The flip side to that is we do see good old economies of scale, where if you have lots of warehouses all over the entire world, which DHL has, very hard to replicate up until recently. Up until recently, that was very hard to replicate because when you talked about logistics, you’re talking about a physical operation. Warehouses, dudes moving boxes, cars, trucks, loading, unloading, very physical. Takes a long time to build a global, regional or national logistics network, a barrier to entry economies of scale. Now that these systems are going digital, You can, and I’ll talk about how JD Logistics is doing this. It’s getting a lot easier to build a network because… really becomes about the digital backbone that connects everything in the robots and the cameras. And if somebody has a building, you can come along with your software and hardware and just turnkey put it in, and that building that someone else owns becomes effectively a warehouse in your network. So those dynamics are changing pretty good right now. You know, there’s a lot of interesting stuff going on within logistics networks. They really are kind of their own animal when you think about them. You can say the same thing about airline networks, which also operate with a hub and spoke system. You can look at waterways, which usually go to certain places. You can look at road networks. Pipelines are pretty interesting. So all of these sort of physical networks. are somewhat similar to digital networks and somewhat similar to people-based networks, but they are different. And as I wrote about this in the book quite a lot, but physical networks are kind of interesting. Big surprise, Buffett’s been thinking about them for like 50 years. Okay. So, a little bit of theory for you, I guess, today, but let me get into sort of JD logistics. Now, I’ve been writing kind of a lot about JD logistics, really since… Four to five years before they went public and then once they went public I suspect I’ve written more about them than almost anybody If you if you ever Google anything with JD logistics, you’ll see my website come up But I’ll give you the the you can go on the website go to the company library look up JD logistics or just JD And you know, I spent like a day hanging out with the delivery dudes. I’ve toured their smart logistics factories in Shanghai Even their drone facility, which is really pretty cool This is kind of a funny factoid. Robin Liu, the founder, he came from a very poor town village in China. And famously the company lore goes, which may not be totally true, is he kind of hiked his way to Shanghai with no money in his pocket and got there from his small village. He started JD in Beijing, physical stores, you know all the history there. I’ve talked about it factoids is when he started going into say call centers because if you run a big e-commerce site focused on quality you have to have people pick up the phones to handle problems. He pretty much put all well not all of them but the majority of his call center people are in his hometown which was a very small village. So he’s kind of like mayor or it’s not mayor but he’s a massive drone fleet there. So we went to visit his drone fleet. They went to his small hometown and that’s where they take out of. It’s just kind of, I don’t know, it’s just quirky. Anyways, you can look it all up but basically it’s, I don’t really even know what to call this animal. When you build a massive logistics network and you digitize it, what you’re really thinking about is you’ve got IoT. edge devices, cameras, robots, all that stuff is being put in place. You have 5G connectivity. which connects those edge devices, and then you have cloud and AI. So you’ve got this increasingly complicated and smart system that’s able to do things, and it’s getting smarter and smarter and more autonomous. So it’s a really interesting animal, but you can sort of break it into pieces. You can look at a nationwide network of autonomous trucks, trains, and drones. You can look at a national network of digital warehouses filled with robots, eventually. You can look at this sort of shifting picture operational footprint of drop-off locations. Are these sort of lockers outside of people’s houses where that sort of things get dropped off? Are they going right into the house? Do you pick them up? I mean, that sort of… Delivery last mile question has been changing pretty quick. And then powering this whole thing, you have increasingly intelligent AI. So it’s a really, it’s hard to characterize what this is. Is it a capability? Is it a service? Is it an innovation platform? Is it an operating system that other people can build apps that run on this thing? Not totally clear. Anyways, so when I was talking with JD and I sort of, who would you like to talk to? I said, I absolutely wanna talk to someone in smart logistics. And they connected me with a man named Mr. Wen, Joe Wenming, who is basically the head of the smart logistics park. And I’ll write this up in more detail. And those of you who are subscribers, I’ll send you at least two, probably three articles on JD Logistics in the next week or so. I’m going to kind of go in depth. But just a little background of Mr. J. I grew up in Yunnan, which is southwestern China, kind of near the border of Vietnam and Thailand, or not Thailand, but more like Laos and Thailand. Beautiful part of the country, by the way. He grew up there, did a bachelor’s degree at Tsinghua University. For those of you who aren’t familiar, like getting into Peking University and Tsinghua University, which are sometimes called the Harvard and MIT of China, both in Beijing, right down the street you can walk from one to the other, it is so exceptionally difficult. Like it’s staggering. You have to take the gaokao, which basically Chinese for high test. That’s the college entry exam. The whole country studies for this thing for years and years and years like maniacs. On an annual basis, about 10 to 11 million high school students in China take the test. It’s a huge event. Of those, the top of the top of the top. get into a Tsinghua and Peking University. You’re not talking about 1%. You’re not talking about how, you’re talking probably about the numbers I pulled. A tenth of 1% of all the 10 million people get accepted into say Tsinghua. So when someone says, oh, I went to Tsinghua as an undergrad, you’re dealing with someone who’s got some fairly big IQ points. Okay. So he goes on there, he ends up doing a master’s degree at Chinese Academy of Sciences, and then he basically joins JD 2012. He’s working on a PhD right now, but basically a computer science guy with some pretty awesome credentials. Anyways, so I talked with him and I kind of had three to four takeaways which I’ll tell you about. I’ll do a quick rundown on JD logistics, basically integrated Now the differentiating factor, and now they’re operating this as a service. It came out of JD. We do this for our own e-commerce business. How we offer it as a service, that’s JD Logistics. It went public in Hong Kong a couple years ago. Their big differentiator against other people who offer logistics and film and service like FedEx. There’s actually a lot of express delivery companies in China, it’s a pretty ruthless space. Most of those offer one step in the process. Express delivery is kind of for one type of package. Cargo freight is for another. I mean, there’s a whole series of sort of logistics transportations. Well, JD is offering end-to-end integrated fulfillment as a service. So they’re doing everything. Express delivery. Taking big furniture pieces out of factories and putting them in warehouses so-called first mile as opposed to last mile They’re doing cold chain refrigerator trucks for perishables fruits and vegetables medical Pharmaceuticals as well bulky they’re doing apparel FMC. They’re doing everything and they’re offering Unique solutions for each one of those categories based on the fact that they can do an end-to-end companies like Nestle, Unilever, Volvo, who are some of the companies they’re working on. Those who are subscribers, I’m going to send you some case information about how they’re working with those. Now why do you want an integrated solution? Well this is Steve Jobs 101. You know he wanted to control everything on the smartphone because it was a new type of technology and if you have an integrated system you have end-to-end control, the user experience is time. It usually takes an integrated approach, which is what Elon Musk is doing with smart cars. And then as the system gets more developed and they kind of know, because everything you basically have to build every step of the process and make it work with all the other steps because nobody’s really built it for us. So there’s not like suppliers you can call. So you kind of do an integrated approach first, then as the product or service matures it tends to become more Android smart cars will be this way. But that usually comes a little bit later. So they’re doing integrated end-to-end service. So everything works cleanly with the other components. The other thing that gives you is tremendous data because you can see everything if you have an integrated process. Now, if you’re doing modular, then people fight over who gets data all the time. You can hear this happening between say Alibaba, Sineo, and various express delivery companies in China. You’ll see in the press every now and then, they’re fighting about who’s not sharing data, or who should be, but isn’t, things like that. Okay, so you’ve got the system they’re building. Now, you can break that into the physical components, and you can then look at the hardware and software they’re building on top of that. Physical components, they basically say they have six physical networks. I think it’s all one thing. So they have a bunch of warehouses. Fine. That’s one thing. They’ve got about seven, let me check, the 1,400 self-operated warehouses. So that’s their backbone of their network. And then they have another 1,700 owner-operated sort of cloud warehouse. This is where someone else owns the warehouse. They own the real estate and then you plug in JD, the software and the plug and play and turn it into basically one of the networks that can then link right in with your core network of 1400. And that’s up. When they went public a couple years ago, those numbers I gave you are 2022. You know, when they went public a couple years ago they had about 800 warehouses, self-operated. Now they’re at 1400. But they call that the open warehouse platform. Pretty cool. That’s one physical component, which they call a network. The other one is the line haul transportation network. Okay, this is things moving back and forth. in trucks between the warehouses. Excluding delivery, which is a different animal, they’ve got about 95,000, 100,000 trucks and vans in their fleet. Plus they got another 200 plus sorting centers. So this is things moving in trucks, they get sorted, and then they go to these major warehouses. The last mile delivery network, which is it’s a pretty complicated thing. That’s whenever you hear, oh my God, JD has 200,000 employees. Well, like 190,000 of them are in, well, not a hundred and a hundred plus thousand of them are in delivery, right? They’ve got a huge number of these people. They got about 7,600 delivery stations around the country. So basically they have a delivery station. within 10 to 15 minutes of everybody’s home. So they’ve got one in every neighborhood. Those delivery stations then connect with the major warehouses. That’s how the network works. Okay, so those are the main pieces. Outside of that, they have what they call their bulky item logistics network. That’s 86 warehouses and 100 sorting centers that are specific for bulky and heavy items. That’s furniture. home appliances, refrigerators. You can’t put those through the regular system. They, you know, the inventory of those things is a real pain because they’re awkwardly shaped. You can’t standardize pickups, and they actually take up a lot of space. So you need these big warehouses. After that, we have a cold chain. They have about 120 of those warehouses. They have about a thousand refrigerated vehicles. And then their cross border logistics network. Okay, that’s when they start going international, which is, more and more of that actually. They’re not like Sineo where they’re trying to build a global network. They’re basically building a China network but the supply chain does extend outward. If you’re buying something from France, you know as a Chinese consumer, it’s gonna come in through the supply chain into their network. So they got 90 bonded warehouses around the world. They got overseas warehouses, a lot of that. Okay so you got six or seven parts to this physical network. And then on top of that, they have sort of three software systems. They have a warehouse management system. They have a transportation management system, and then they have an order management system. Fine. And that runs the warehouses. It runs the trucks, the line network, and then it runs the order management. This order is going to be processed here. It’s going to be drawn from this inventory. Here’s the route we’re going to use and so on. So it’s sort of software and hardware. And you can see as they start to get better at this, they can go to other people’s warehouses in China and plug and play the software and increasingly the hardware, the robots and stuff. But they can also take that outside of China and offer it as a service. So and you can see there, I think they’re doing that a little bit. Okay, so that’s kind of the basics of JD logistics. And it’s worth keeping in mind. When you’re competing in logistics, it’s really pretty simple. It’s not like a consumer business where you’re trying to make people happy. There’s just a couple of KPIs. Number one, efficiency. How fast and cheap are you? That’s what people care about. You know, and being cheap is a huge part of the game. So all of this system is about driving and capturing productivity gains. You know, let’s replace a lot of people with robots and let’s be more efficient at everything we do. So capturing operating efficiency is a huge deal. You get rid of certain distribution layers, you get quicker, you increase your inventory turns, you optimize your inventory management, all of that. Second to that, the customer experience, big deal. That’s really when people talking about customer experience with logistics, they’re usually talking about delivery speed. It’s pretty much a lot of what they’re talking about. And sometimes it’s a little bit more than that. Like if you’re doing apparel, it’s a lot about returns. Because people tend to return clothing a lot. So it’s not just the user experience, hey, it was fast. But it’s also, oh, I had to return the sweater. How do I do that? But usually when people talk customer experience, they’re talking speed. And then finally, you think about intelligent decision making and forecasting. You know, if you’re a company, how many of these do we need to have in the warehouse? Where do we need to keep all of our Nestle items in the local warehouses right next to the convenience stores? Or do we put them outside of town? What do we put where? That sort of prediction stuff is incredibly important. And if you’ve got an end-to-end integrated digitized logistics network, you can get very good at that. Okay, so that’s kind of the basics. Now let me sort of jump to the so what of, look, here’s what I learned talking with Mr. Ju. Okay, lesson number one, take away number one. The major digital transformation moves have already happened. If you look at what logistics is traditionally, a lot of people, a lot of dudes in warehouses, a lot of moving things on and off in trucks, a lot of what we would call repetitive labor work. Okay, the automation, the robots, all of that stuff, it’s already there. It’s just a matter of execution. It’s not like there’s groundbreaking tech to be done. So these automating solutions, it’s all about sort of adoption and execution for inbound and outbound logistics, a lot of sorting And so you can start to see warehouses basically being, it’s weird when you go into FedEx. I went one time to, I think it was DHL, it was like the DHL hub in Guangzhou. And it was this massive facility. For China, the big players like DHL, FedEx, they do cross border. There’s different licenses and things for intercity and intercity. So those major Western players, international players, they do the cross-border hub. So someone like out of Guangzhou or Shenzhen to the rest of the world. So you go to these major facilities, there’s nobody there. That’s easier because they’ve standardized the box and stuff, but very few people, these huge facilities, so they were already pretty lean operations in terms of their conveyor belts and stuff. Okay, now that it’s being more and more automated and robotics and sensors, that’s already playing out. So that automation and robots piece already happening. The other major sort of, let’s call it big digital transformative move is the data. It’s digitizing the process, digital twinning the process, looking at the data. Okay, that’s already happening as well. It’s being deployed and it’s really pretty awesome. Like when you think about, if you’re an e-commerce company, if you’re a TikTok, if you’re a media company, you’re kind of a digital native from the get-go. Aspect to start to get the data to see everything you were kind of born digital Okay, that’s cool. The weakness of those companies is their data is actually somewhat shallow Because all of their data is about the digital world. Oh, here’s what Jeff clicks on on tik-tok it’s not nearly as rich or as deep as data from the physical world. So when you look at these logistics hubs, they are really getting this fascinating combination of digital data, people doing orders, but high quality data coming from robots and devices deployed everywhere. cameras, sensors, RFIDs on every package. I mean, they’re getting much better data, which enables really good management and increasingly better real-time control of operations. It’s really, IoT deployed at scale gets you really amazing data from the physical world, and it lets you start to optimize operations in the physical world. We haven’t really seen that yet in too many industries, but this is a place where you can kind of do it because it’s in a world that you control. It’s not like you’re deploying sensors along the streets that have evolved over hundreds of years. No, you’re creating these warehouses and these trucks. So it’s a very controlled environment so you can sort of design it to generate good data. Anyways, so JD Logistics, it’s a operation company and a tech company. That’s very different than a lot of the digital natives we sort of talk about. Okay, so that’s kind of lesson number one is look, we’re already seeing these things. The biggest payoff in terms of those KPIs I just mentioned, you’re gonna see big efficiency gains in logistics. It’s already happening. Things are going to get cheaper. Things are going to move around the world more efficiently. And big surprise when you make something cheaper, people use more of it. So we’re going to see lots of more physical objects just moving around. It’s one of these secular trends I like to think about. Like when you look at a secular trend, if you’re an investor or someone like China, you might look at population growth as a secular trend that’s gonna shape growth. Another secular trend that tends to happen when countries get wealthier and wealthier is the number of physical objects on trains, on trucks, keeps increasing year after year. It just sort of goes up in a straight line. It’s kind of an interesting number to look at. Okay, so that’s lesson number one. The major moves have already happened and we can sort of watch a couple companies for deploying this at scale. Okay, lesson number two. In all of this, there’s an interesting balancing act when you deploy, when you develop the technology and deploy the tools and start to target use cases, there’s an interesting challenge in balancing efficiency, cost, and the user experience. And this is, let me put a qualifier on this whole thing. This came out of an interview with Mr. June. Nothing I’m saying here is a quote from him. Nothing I’m saying here is a statement by him, an opinion by him. This is my own things that I’ve sort of gleaned talking to him, reading reports. So let me make sure I’m not speaking for anyone but myself here. But there’s this idea of, you know, logistics is so sensitive to cost. I mean, it’s like airlines. Like if you can drop your ticket price by $20, everybody switches. right? It’s the same thing. Super sensitive to cost. So you want to deploy the right technology at the right part of the right use case to drop that cost. But you don’t want to spend too much money on the technology developing and maintaining because that also costs money. So the way I’ve heard this described is you end up having in practice to spend the least amount of money possible to solve the hardest problems. The hardest problems, the ones that will get you the biggest cost gains, you kind of got to go after those, but you got to do it in a way where you’re spending as little as possible. So it’s this kind of interesting game. Now areas where, you know, I can ask where are we seeing big improvements right now? Like with all of this, where is the needle moving? in terms of efficiency at cost. And basically robots for picking and sorting. how most warehouses and trucking systems work is you have people running around all the time to get things and take them somewhere else. We gotta go to the truck, we gotta take it off the truck, we gotta put it on the landing bay. Then we gotta take it from the landing bay and we gotta put it in the inventory in the back of the warehouse until it might be needed. Then when we get an order, we gotta go to the, you know, the inventory shelves, we gotta pull it and then start, you’re sending people to go around and get stuff. You don’t want that to happen. You want the robots to do that people to stand in one place and everything is brought to them to then be assembled into packages. So that’s basically everyone’s building robot armies. and it’s QR based and 5G is a big part of this because you can control the robots much, much better, especially when they’re all in one tightly controlled location like an automated warehouse. So in the past pre 2019, JD was using a wifi guided system for their robots, which were pretty primitive back then. I remember going in to see them. Okay, now they got 5G everywhere. They’re deploying this. So this like… Yeah, this train has left the station robots for picking, sorting 5G enabled, you know, go, go, go. And then autonomous delivery for consumers. That’s another major cost item. If you can knock that one down, you’re going to see a big thing. Big savings. So we see autonomous vehicles. Usually in business parks in China, you also see them in college campuses a little bit, but mostly business parks, again, a controlled environment. We do see them on the roads a little bit in places like Suzhou. But yeah, I think last time I checked 400 to 500 of these vehicles are being tested around China. And it was that’s going to be the other big lever where the cost really moves. But again, you have this difficulty of targeting the biggest problem, but doing it as cheaply as possible. Difficult areas are anything you can’t standardize. So that’s furniture. Big bulky items. That’s why there’s a separate network. You know, really kind of difficult. The warehouse is expensive because it’s gotta be huge because you have to store all these sofas. You can’t like have them coming down a conveyor belt with a little robot picker pulling off the RFID tags. Everything is too big for that. And there’s world the difficulty in furniture and bulky items. Fresh produce is another problem. You know, apples are not standardized. How do you know if this apple is good and that apple is not? Even though they’re roughly the same size, not very standardized, very very difficult. Okay, so that’s kind of point number two. Lesson number two. Lesson number three. FMCG seems to be where this end-to-end fulfillment solution is getting real traction. And those of you who are subscribers I’m gonna send you these studies about like Nestle and Volvo and where they’re using this in China. Because you can think about like FMCG it’s all about the last mile. The orders are going to come in at a very high frequency. We want to buy coffee, we want to buy a soda. All of these things, the orders, whether they’re in person or online, come in very frequently all day. People walking into convenience stores, gas stations, supermarkets. So you’re doing rapid replenishment all the time. Well… Where should you keep all that inventory? How should you manage it? Well, that’s a end-to-end integrated smart logistics network with a really good FMCG solution. That’s a pretty interesting idea. And the data is important and some of it stays in your warehouse. So there’s a lot going on there that you can go after. So not a big surprise that FMCG is seeing serious, I think, significant adoption by these B2B service sales. Kind of interesting. I’ve put the sort of graphics for how they do FMCG versus bulky versus cold chain versus apparel. I’ve put those graphics in before. I’ll put one or two of them in the show notes for this one. Automotive looks like it’s getting interesting. If you’re selling Volvos in China, as a Volvo, you’ve got dealerships, but you’ve got all these auto repair places that have to constantly be stocked with all the appropriate products for whatever night you’re in the air within a Volvo. So that’s kind of an interesting situation in terms of this sort of integrated solution. So those two automotive FMCG seem to be pretty compelling. And that’s sort of number three. And last point. I think this is totally me. I think the business model is gonna change. I think we’re gonna see a major, I think as this thing gets more and more digital, I think what we think of as a logistics network, we know those business models, take orders, deliver. I think it’s gonna change. I think it’s gonna become some combination of a consulting firm with huge amounts of data. I think it’s going to become customized delivery and fulfillment solutions and maybe a data provider solution. I think we’re going to see different business models. And the three I’m sort of thinking about are, is it going to become an innovation platform? Are they going to take the system and start basically putting up APIs where anyone can sort of, well, developers and companies can then tap into all the data? that is flowing through this logistics network all the time. That would be a very interesting move. Are they gonna go further and let people build apps and other things on top of it? At that point, you’re starting to look like an operating system. I don’t know, that’s kind of a huge idea. I’m not sure what I think about that. So that could be a business model. Another business model which I think we will see is a production ecosystem. which I’ve written about nine common business models in digital. One of them’s a production ecosystem, which is you digitize the entire supply chain of a service. You make all the data connected, you start to get better. That’s basically kind of what they’re doing if you consider this sort of a linear service. And then the third one is a consumption ecosystem, which is where you’ve digitized your own operations. Now you start to connect with complimentary services. your own logistics service and your data insight service and your consulting service as JD Logistics, which is where I think they’re going. You’re also connected in real time with other companies that do complimentary services and it’s all integrated as one solution. Consumption ecosystem. Yeah, you could see how that’s going to work. So I think production ecosystem for sure. I would bet consumption ecosystem and then innovation platform. I’m not sure. And that’s sort of my fourth point for this. So how are we doing on time? Not too long for today. Fascinating subject, those of you who are subs, I’ll send you, you’ll get a whole lot about this in the next day or so. Those of you who are going to China, you’ll get to walk around and see all this stuff in person, it’s pretty. I remember visiting the JD Robotics Lab. 2018, 2017 and they were you know they were really doing the full process themselves. They were building their own robots, they were building their own warehouses, they were doing every they were building their own drones, they built their own drone fleet, they were doing everything internally like Richard Lio. I mean he’s a very bold businessman and he went all in on we are going to build our own in-house logistics network end-to-end and he’s really been on that path from 2008. when he brought this all in house for the first time before they digitized it. Anyway, super cool company. For those of you who are investors, Michael Burry, you know the the big short guy, he’s been invested in JD for since about 2018. Back when I think 2000, don’t quote me on that. I know since like January, if you look up Michael Burry, that he has had significant positions in JD and Alibaba, for at least recently, and I think for several years. So it’s kind of one of these companies, everyone knows Alibaba, people don’t know nearly enough about JD, it’s a really interesting company. It’s been one of my favorite China companies for a long time. Anyways, that is it for content for today. I hope that’s helpful. pretty fun. I know I’ve sort of gone off into generative AI a lot. I’m gonna sort of get back to meat and potatoes, looking at companies, doing sort of standard, you know, strategic analysis of leading digital companies more than I have been the last couple of months. Anyways, that is it for me for content. In terms of fun stuff, I’ve just been working away. I’m getting ready to go back on the road. Most of June, most of July, gonna be on the road. China, Asia, and June. I usually try and I move my home base in July and January somewhere else. So going to be in Europe for most of July. I’m looking forward to that. Oh, I had a funny experience the other day. I’ve been looking for some way to, you know, do a large language model, or at least small language model, on my own content on my web page. So it’s very specific, like Ask Jeff, and it’ll sort of draw off all my podcasts and everything for, you know, 10 years. Sort of digitizing my brain, I guess. And you know, I finished transcribing all the podcasts, it’s all being loaded in. I’m pretty close to being done, but I’m looking for the right service. a company called Ask AI which was sort of interesting. There’s a company called Chatbase which is sort of a coded version of this not an AI version no code LLM version and there was another company called BotSonic which has got a service. Anyways I joked last week that I get these let’s call it marketing emails every day with, hey, we’ve got someone who wants to be on your podcast. Then usually this is content marketing by companies. They hire marketing firms to try and get their people on podcasts. And then it’s a form of content marketing, right? Which is fine, but they come every day, every day. Literally as I was looking at Botsonic in my email box, it was like another one of these emails. And it was like, we have a guest for your podcast. So and so at botsonic. literally the company I was looking at. Yeah, right then. So I was like, okay, let’s talk. I don’t know if I don’t have guests, but yeah, I’d like to talk. So that’s kind of an interesting company. There’s a bunch of these. I think it’s going to happen sometime soon. Like it’s just clearly the way the world is going. Someone’s going to figure out a good simple app for doing this. Yeah, but it’s this whole idea like the The simple version of this is instead of reading content, you have a conversation with content. Okay, that’s what this would be. The weirder version of this is like, did I just digitize my brain? Like, is this a virtual me? Like, how good is this thing gonna get at answering questions like I ask about my own thinking and content? Cause I’ve got 160. Podcasts, you know, 11 books, whatever it is, hundreds of articles. I mean, if you digitize all of this and put it into one thing, that is kind of a lot of my own thinking in one place. So is this going to be a digital version of me? Maybe you ever for those of you like comic books and stuff, if you ever read Iron Man, like that’s what like. 15 years ago when Iron Man comics were out, that’s what it was, he digitized his personality and after he died, which is what they’ll do in these Marvel movies, like these Avengers movies now that Tony Stark is dead, he’ll come back as a digital version of himself that talks to people and deals with people. Anyways, it’s a weird idea. Yeah, maybe. I think it’s kind of cool, but anyways, that’s it for me. I hope everyone is doing well. Take care and I’ll talk to you next week. Bye-bye.

I write, speak and consult about how to win (and not lose) in digital strategy and transformation.

I am the founder of TechMoat Consulting, a boutique consulting firm that helps retailers, brands, and technology companies exploit digital change to grow faster, innovate better and build digital moats. Get in touch here.

My book series Moats and Marathons is one-of-a-kind framework for building and measuring competitive advantages in digital businesses.

This content (articles, podcasts, website info) is not investment, legal or tax advice. The information and opinions from me and any guests may be incorrect. The numbers and information may be wrong. The views expressed may no longer be relevant or accurate. This is not investment advice. Investing is risky. Do your own research.